400-9988-900

400-9988-900

400-9988-900

400-9988-900

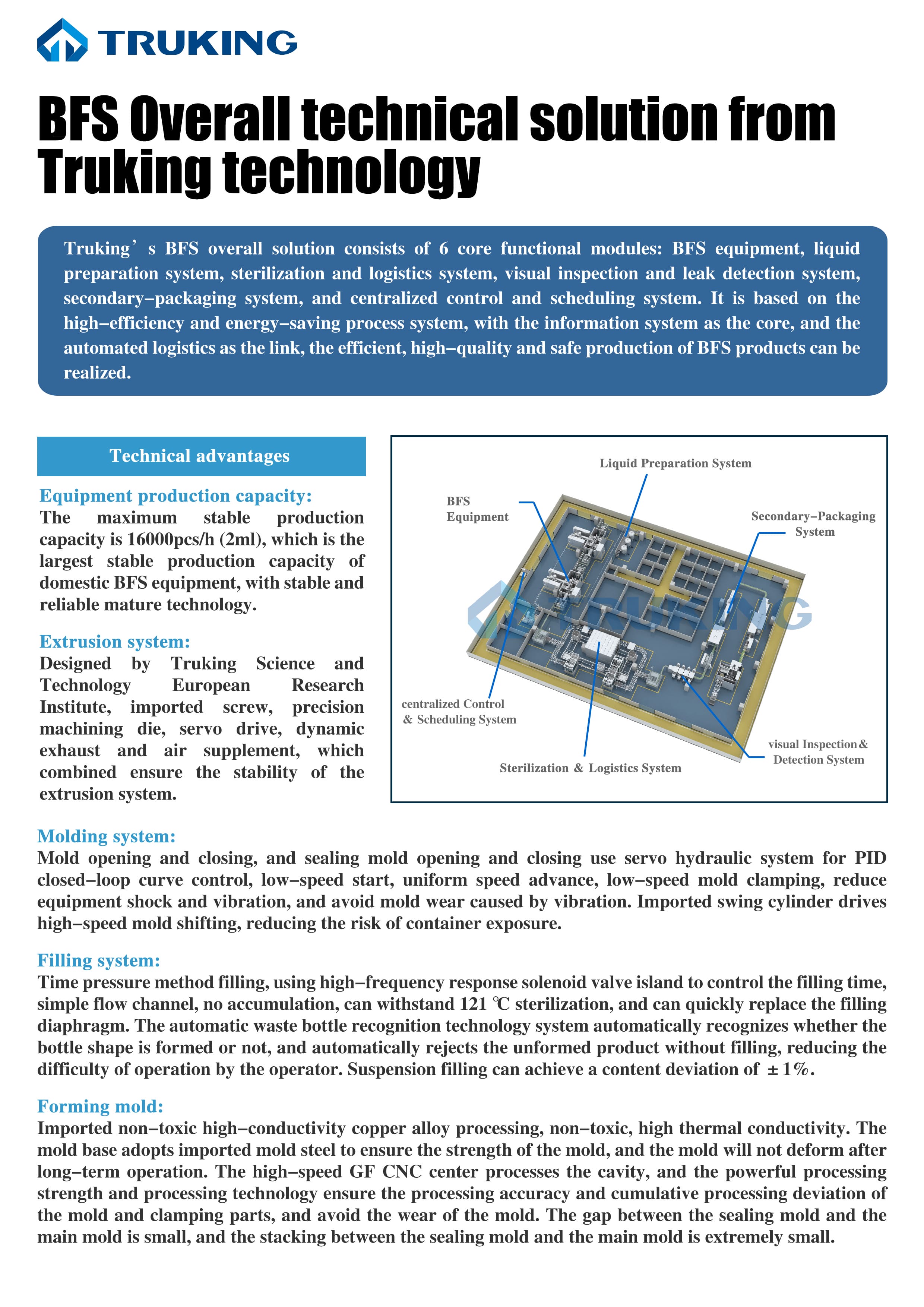

Truking’s BFS overall solution consists of 6 core functional modules: BFS equipment, liquid preparation system, sterilization and logistics system, visual inspection and leak detection system, secondary-packaging system, and centralized control and scheduling system. It is based on the high-efficiency and energy-saving process system, with the information system as the core, and the automated logistics as the link, the efficient, high-quality and safe production of BFS products can be realized. Truking can provide a full set of production equipment.

Technical advantages

Equipment production capacity: The maximum stable production capacity is 16000pcs/h (2ml), which is the largest stable production capacity of domestic BFS equipment, with stable and reliable mature technology.

Extrusion system: Designed by Truking Science and Technology European Research Institute, imported screw, precision machining die, servo drive, dynamic exhaust and air supplement, which combined ensure the stability of the extrusion system.

Molding system: Mold opening and closing, and sealing mold opening and closing use servo hydraulic system for PID closed-loop curve control, low-speed start, uniform speed advance, low-speed mold clamping, reduce equipment shock and vibration, and avoid mold wear caused by vibration. Imported swing cylinder drives high-speed mold shifting, reducing the risk of container exposure.

Filling system: Time pressure method filling, using high-frequency response solenoid valve island to control the filling time, simple flow channel, no accumulation, can withstand 121 ℃ sterilization, and can quickly replace the filling diaphragm. The automatic waste bottle recognition technology system automatically recognizes whether the bottle shape is formed or not, and automatically rejects the unformed product without filling, reducing the difficulty of operation by the operator. Suspension filling can achieve a content deviation of ±1%.

Forming mold: imported non-toxic high-conductivity copper alloy processing, non-toxic, high thermal conductivity. The mold base adopts imported mold steel to ensure the strength of the mold, and the mold will not deform after long-term operation. The high-speed GF CNC center processes the cavity, and the powerful processing strength and processing technology ensure the processing accuracy and cumulative processing deviation of the mold and clamping parts, and avoid the wear of the mold. The gap between the sealing mold and the main mold is small, and the stacking between the sealing mold and the main mold is extremely small.

Edge trimming system: PE material is cut inside the mold, and PP material is trimmed by servo electric cylinders to transfer the sheet material, with precise positioning and fewer edge burrs. The unloading part is driven by a single-axis servo cylinder with a repeat positioning accuracy of 0.01mm. The position of the cylinder can be adjusted on the HMI interface. When switching between different specifications, the unloading position can be adjusted to match without adjusting the height of the reclaimer. The debugging is simple and stable.

Hydraulic system: servo hydraulic pump station, PID adjustment of outlet pressure, closed-loop curve control of cylinder action, when the system does not need to supply oil, the pump station switches to low-frequency circulation, reducing the energy consumption of the hydraulic pump station. In the manual state, the hydraulic pump station runs at low speed, which facilitates equipment debugging and maintenance, and improves personnel safety protection.

CIP/SIP system: CIP/SIP pipeline and liquid medicine circulation system, use low-residue combined valve and T-valve, to avoid residual and stagnant suspension in the pipeline. Suspension and clear liquid can be switched quickly. All pipelines are individually drained to ensure that the system has no dead spots for sterilization and rapid heating.

Control system: using SIEMENS motion controller and industrial computer control, the action execution is more precise, electronic signature and electronic batch record are realized, and the verification requirements of data integrity are met.

GMP cases: There are mature project cases and GMP verification experience in the fields of plastic ampoule injections, suspension inhalants, solution inhalants, eye drops, etc.